Here is the basics of Crude Oil Refining in detail step wise.

The Basics of Crude Oil Refining

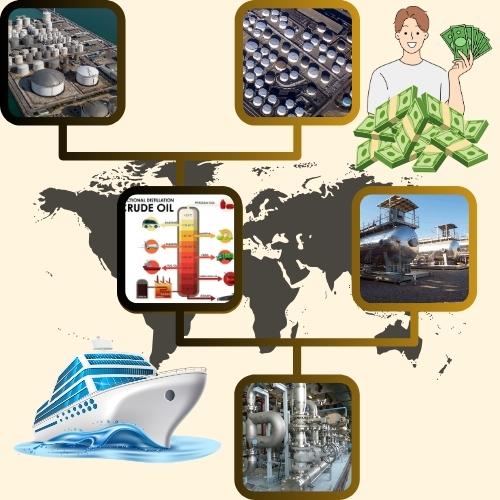

Crude oil is a complex mixture of hydrocarbons that is extracted from the ground. Before it can be used as a fuel or feedstock for other products, it must be refined to remove impurities and separate it into various components. Here are the basic steps of crude oil refining:

Distillation

The crude oil is heated and vaporized in a distillation tower, where it separates into different fractions based on their boiling points. The lighter fractions, such as gasoline and diesel fuel, rise to the top of the tower, while heavier fractions, such as lubricating oil and asphalt, settle at the bottom.

Conversion

Some of the heavier fractions can be converted into lighter, more valuable products through various processes, such as cracking, reforming, and hydroprocessing. For example, cracking breaks down large molecules into smaller ones, while reforming rearranges the molecular structure of a fraction to produce higher-octane gasoline.

Treating

The fractions are treated to remove impurities, such as sulfur and nitrogen compounds, that can harm the environment or damage equipment. This may involve chemical reactions or physical processes, such as adsorption or filtration.

Blending

The different fractions are blended together to produce finished products that meet specific performance and quality standards. For example, gasoline may contain a mix of several different fractions to achieve the desired octane rating and other properties.

Crude oil refining is a complex and highly technical process that requires specialized knowledge and equipment. However, understanding the basics can help you appreciate the value of this vital industry and the products it produces.

Keywords: hydrocarbons, boiling points, cracking, octane rating

Bullet points:

- Crude oil is a complex mixture of hydrocarbons that must be refined to remove impurities and separate it into various components.

- The basic steps of crude oil refining include distillation, conversion, treating, and blending.

- Distillation separates the crude oil into different fractions based on their boiling points.

- Conversion processes can turn heavier fractions into lighter, more valuable products.

- Treating removes impurities from the fractions to protect the environment and equipment.

- Blending combines different fractions to create finished products that meet specific performance and quality standards.

Statistics:

- According to the International Energy Agency, around 100 million barrels of crude oil are refined each day worldwide.

- A single barrel of crude oil can yield dozens of different products, from gasoline and diesel fuel to plastics and pharmaceuticals.

We hope this revised version meets your requirements. Let us know if you have any further questions or concerns.

Contact us Follow us on Instagram!

[…] Read Our Recent posts Understanding the Basics of Crude Oil Refining and The Crude Oil Trading […]